- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

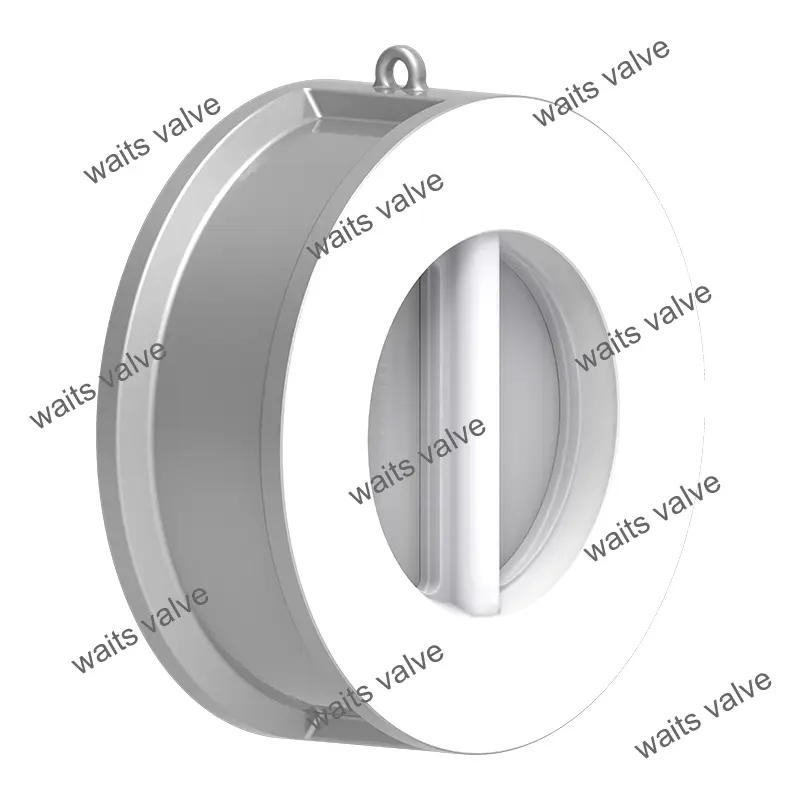

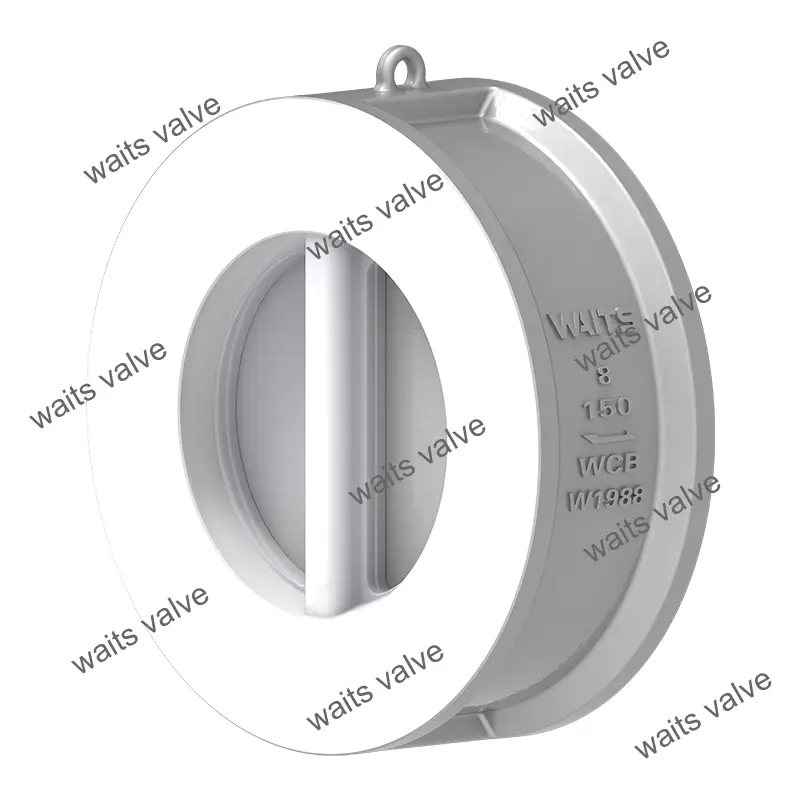

PTFE Lined Wafer Check Valve

Ngantosan klep Valv PTFE dijelaskeun fitur Compos Corronton tahan, linsing ptfe tinggi sareng desain kompak pikeun pencegahan backflow! Ueuh Charvch chacher pikeun transiny sareng harga pragmatis, jelas ngawatesan genep komponén biaya, kalebet supaya, ngolah, pamariksaan sareng waragad sanés.

Kirim Pananya

Manufactured in the Waits Valve factory in China, the PTFE Lined Wafer Check Valve prevents media backflow through a combination of fluoroplastic lining and check mechanisms (such as valve discs, diaphragms, springs, etc.). Its core feature is that the inside of the valve body and the sealing surface are coated with fluoroplastic to isolate the media from the metal parts. These valves are suitable for pipeline systems that convey highly corrosive, high purity or easily contaminated media, and are widely used in chemical, pharmaceutical, electronic, environmental protection and other industries.

All our valves are molded with PFA linings, which are compatible with the most corrosive and toxic chemicals. They can all be used at temperatures up to 392°F.

Our check valves are used in a wide variety of process lines and are often used to:

Maintain static head pressure at pump outlet

Nyegah kontaminasi

PTFE Lined Wafer Check Valve provides simple nitrogen blanketing control

We are confident we can find the right valve for your application.

| Implementation Standards-PTFE Lined Wafer Check Valve | |

| Standar Désain | API 6D/API594/BS1868 |

| Standar flange | Asme B16.5 / ASME B16.47-A / B / en1092-1 / 2 |

| Métode sambungan | Wafer, FF, RF |

| Nguji sareng ditampa | Seuneu 598, en12266 |

| Panjang struktural | Api6d / asme b16.10 / en558 |

| Tekanan sareng rating suhu | Asme B16.34 |

| Ujian ferproof | / |

| Standar bocor low | Iso 15848-1, API 622 |

| Desain anti korosi | Nace Mr 0175 |

| Application-PTFE Lined Wafer Check Valve | |

| Ukuran | NPS 2”~ NPS 12″ DN50 ~ DN300 |

| Kisaran tekanan | CL150 ~ CL150 PN10 ~ PN16 |

| Keungeut suhu | Ptfe-50 ° C ~ + 180 ° C |

| Kangcunan aplikasi | Suitable for water, steam oil, nitric acid, acetic acid, strong oxidizing media and other media. |

| Awak klep | Pamasangan: A10, A182 F34, F344, F316, F316l, F316l, F516, F51, B13, B148, PTF5, MF3, PTF5, MTF5, MTF5, MF3, PTFCE-digedékeun Castings: A216 WCB, CF3, CF8, CF3M, CF8M, 4A, 5A, C95800, LCB, LCC, LC2, PTFE-lined |

| Piring klep | Logam, ptfe-dijejeran |

| Rod | PTFE (F4) or reinforced graphite |

Fitur produk

1.Wafer Type Design:Flat ends for installation between two pipeline flanges, secured by bolts (no welding or additional flange accessories required).

2.Working Principle:

Forward flow: Medium pressure pushes the disc open.

Reverse flow: Disc closes automatically, with the PTFE sealing surface preventing backflo

Kaunggulan produk

1.No separate flanges required, reducing material usage and cost compared to flanged types.

2.Simply loosen bolts for maintenance without moving pipes, good for space constrained areas (e.g., densely packed pipelines).

3.Short disc travel distance, suitable for high flow, low viscosity media (e.g., water, solvents).